Curtain wall

Curtain wall

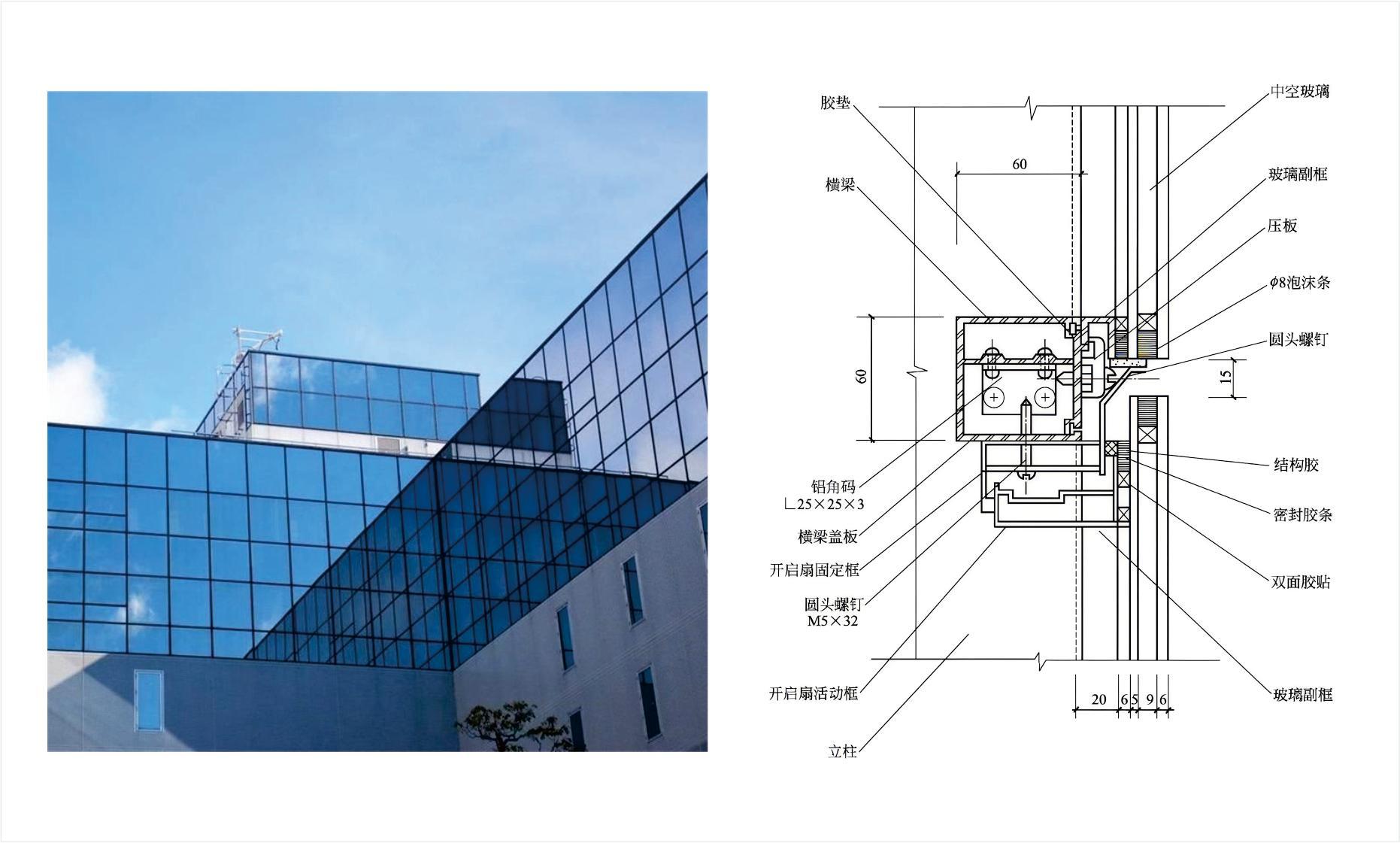

In contemporary architectural design and construction, the outer protective structure has gradually abandoned traditional heavy structures such as brick walls and block bricks, and instead adopted a new type of enclosure system called building curtain walls. Through modular design and industrial installation, building curtain walls can not only achieve rich expression of architectural aesthetics, but also significantly enhance the comprehensive performance of buildings. Its main types include glass curtain walls, stone curtain walls, aluminum panel curtain walls, ceramic panel curtain walls, clay panel curtain walls, metal panel curtain walls, fiber cement panel curtain walls, and other special panel curtain walls, which can be flexibly selected according to building functional requirements and design styles.

The sealing and structural connection of the curtain wall system are the core links to ensure its safety performance and functional use. Silicone structural sealant and silicone weather resistant sealant play key roles respectively, and their performance compatibility directly affects the long-term reliability of the curtain wall.

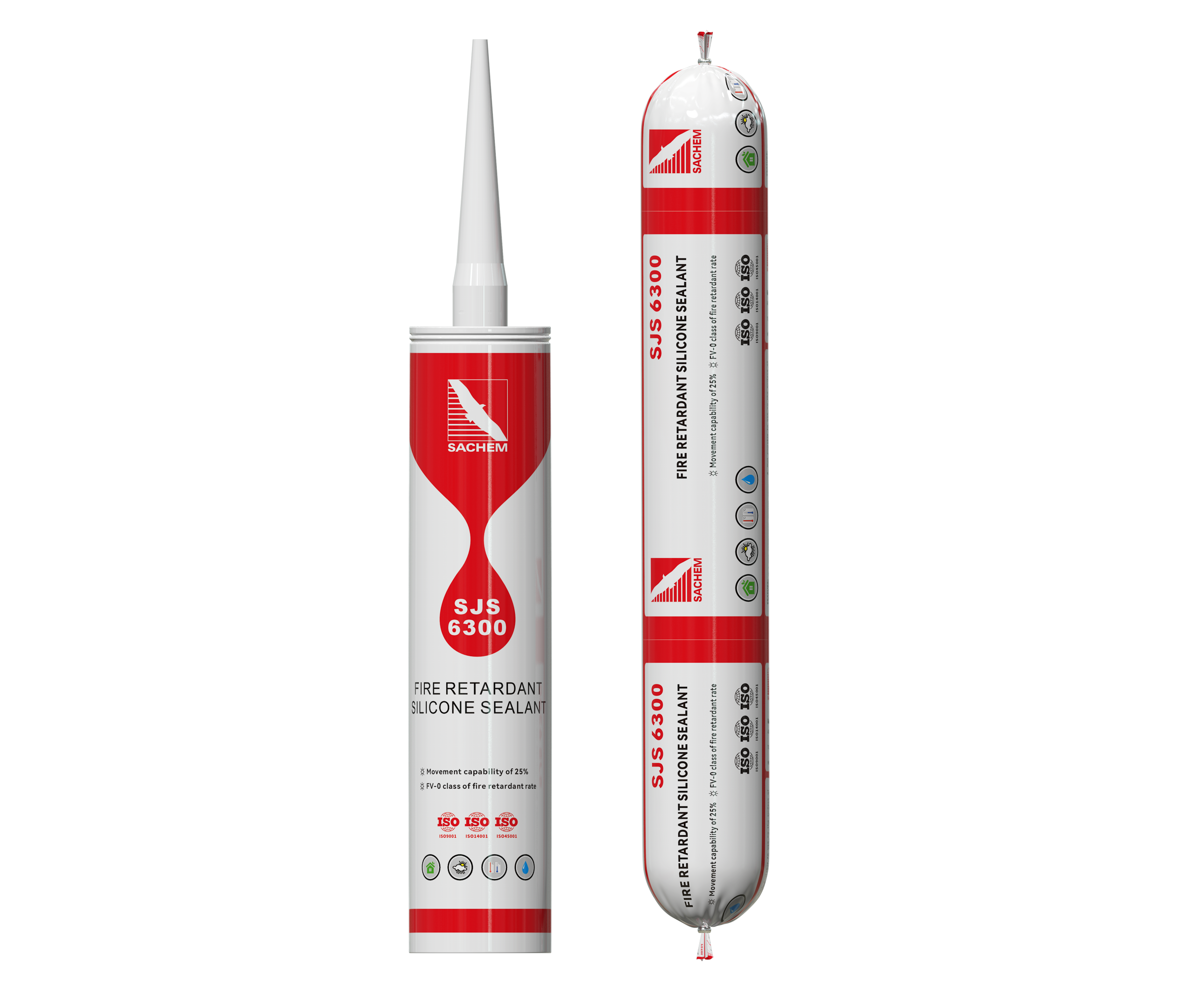

1、 Silicone structural sealant for curtain walls

Silicone structural sealant is an indispensable structural load-bearing material in the Structural Sealant Glazing (SSG) assembly system for curtain wall structures. Its core function is to form a rigid whole between glass panels and aluminum frames through chemical bonding, and then transfer the loads (including self weight, wind load, seismic action, and temperature stress) borne by the glass panels to the main structure through mechanical connections (such as bolt fixation, slot connection, etc.) between the aluminum frames and the main skeleton of the curtain wall.

Technical characteristic requirements:

Due to the complete dependence of the stability of glass panels on the adhesive strength of silicone structural sealants, and the need to withstand the long-term effects of natural environment (UV radiation, high and low temperature cycles, humidity changes, etc.) and mechanical loads throughout the entire life cycle of the building, their performance must meet strict standards:

Must have sufficient tensile strength and adhesive strength to ensure no adhesive failure or cohesive failure occurs under ultimate load;

Long term aging resistance testing (such as artificial accelerated aging test, wet heat aging test, etc.) is required to ensure that the performance degradation is controlled within the allowable range within a service life of more than 20 years;

Moderate elasticity should be maintained to buffer the small displacement of the plate caused by temperature changes, and to avoid glass or adhesive cracking due to excessive rigidity.

Typical application areas:

Hidden frame glass curtain wall: The glass is bonded to the aluminum frame through structural adhesive on all four sides, and the adhesive joint is the only stress path;

Semi hidden frame glass curtain wall: The upper and lower edges or left and right edges of the glass are bonded with structural adhesive, while the other sides are covered with profiles, and the adhesive joints bear part of the structural load;

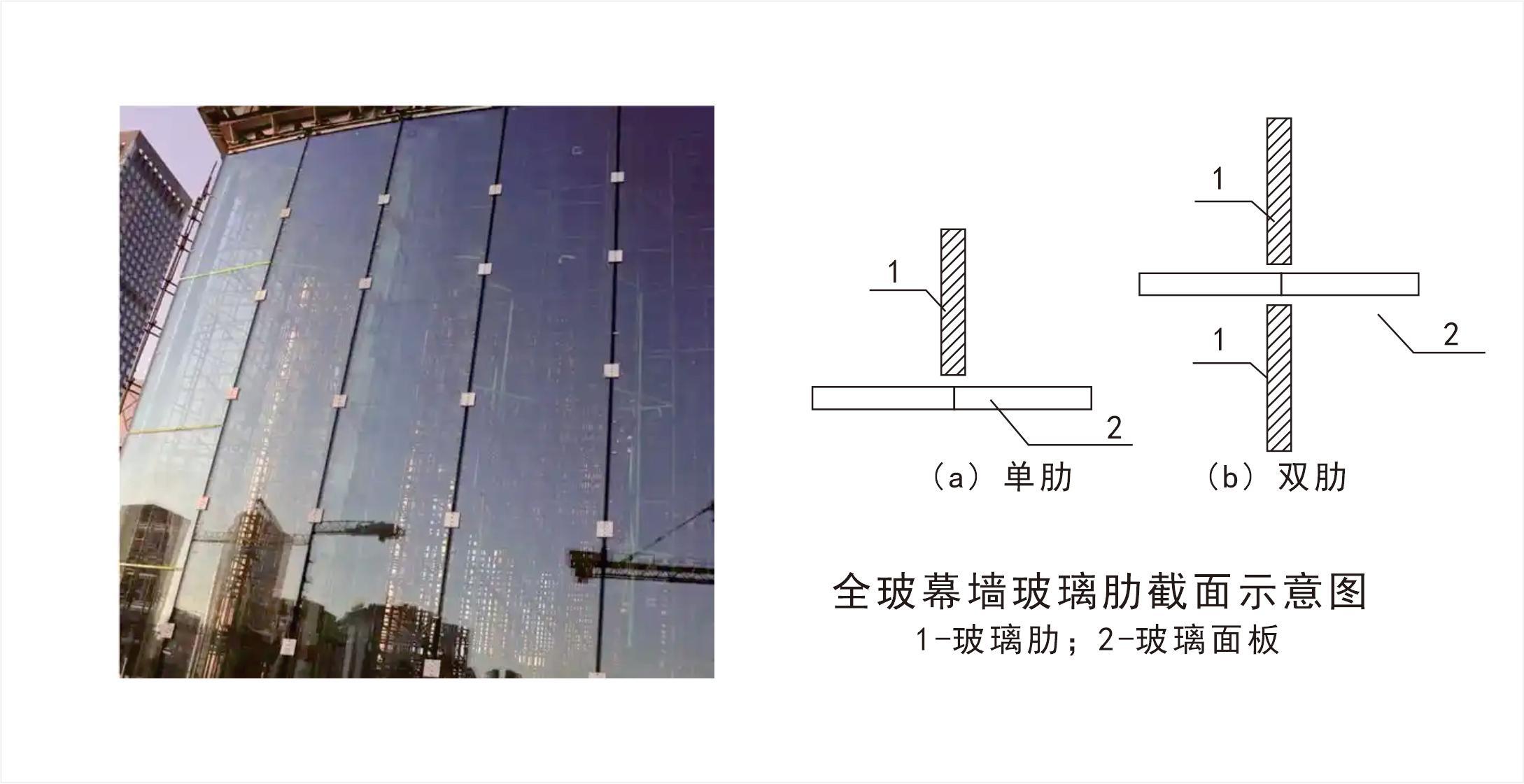

Full glass curtain wall: The adhesive joints between glass and glass, as well as between glass and ground/wall, directly transfer loads. Double sided structural adhesive is usually used for bonding, and the width and thickness of the adhesive joints need to be determined through structural calculations.

Hidden frame glass curtain wall (4-sided structural bonding)

Half hidden frame glass curtain wall (2-sided structural bonding)

Full glass curtain wall (adhesive joint force transmission, double-sided structural bonding)

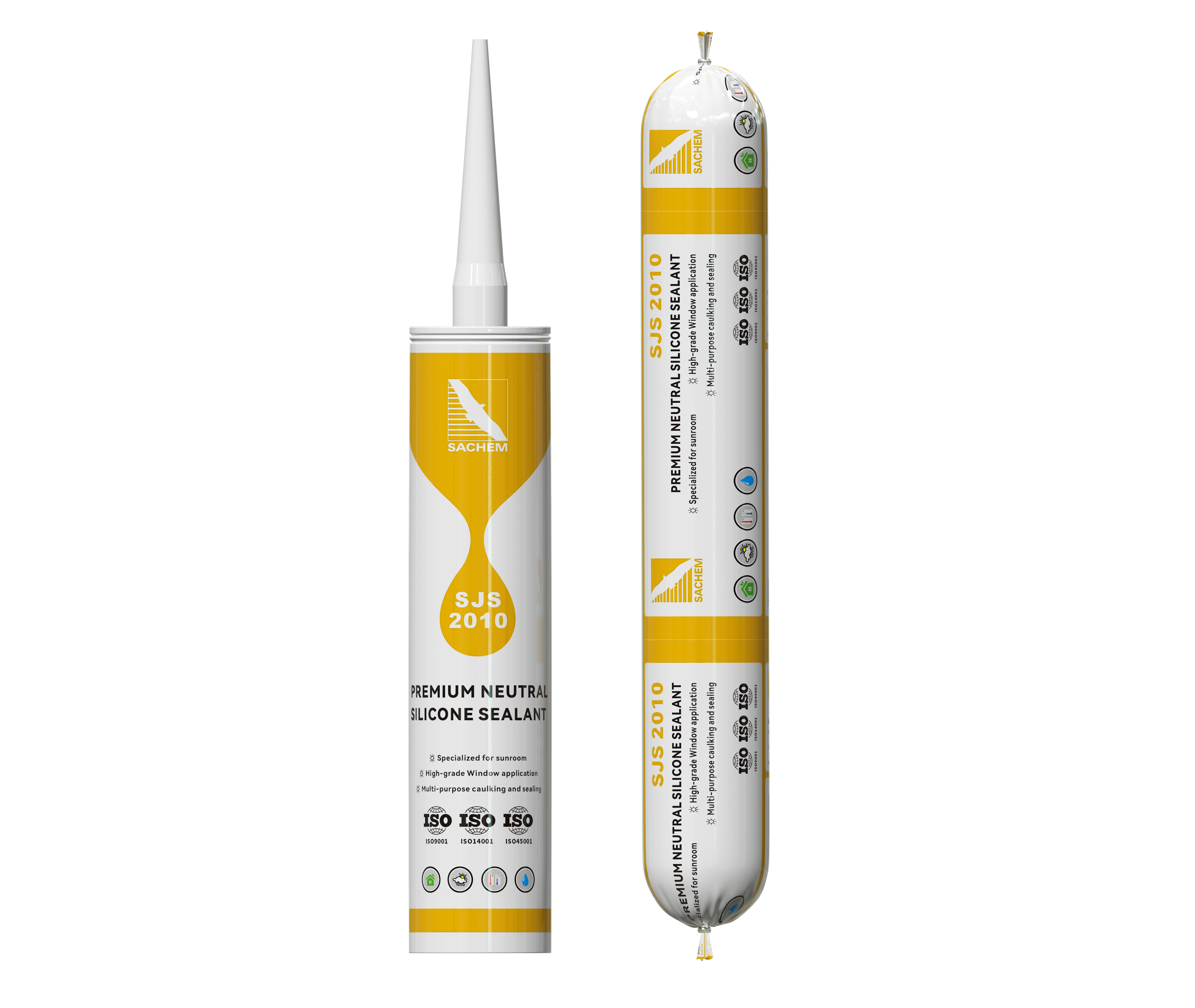

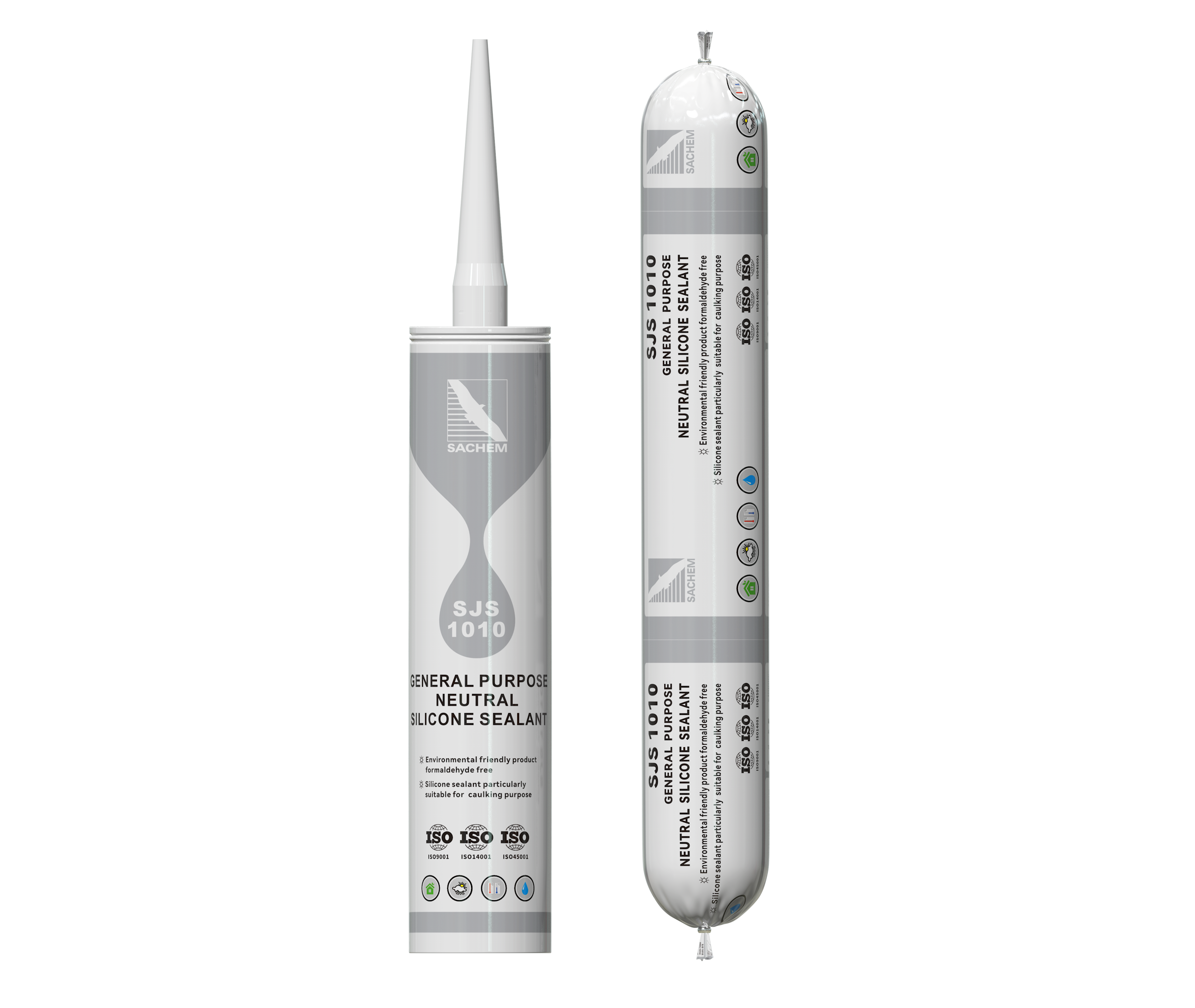

2、 Silicone weather resistant sealant for curtain walls

Silicone weather resistant sealant is mainly used for sealing the joints between different material panels of curtain walls (such as glass to glass, glass to metal profiles, metal to stone interfaces, etc.). Its core function is to ensure the airtightness, water tightness, and dust resistance of the curtain wall system, while isolating external environmental interference on the interior of the building (such as rainwater infiltration, air leakage, noise transmission, etc.).

Technical characteristic requirements:

The joints of curtain walls may experience displacement changes due to various factors during the use of buildings

Material characteristics: Differences in thermal expansion and contraction caused by temperature changes in glass, metal, stone, and other panels may result in joint width expansion and contraction of ± 5% to ± 25%;

Main structure deformation: The inter story displacement of a building under wind load, earthquake action, or foundation settlement can cause shear or tensile deformation of joints.

Therefore, silicone weather resistant sealant needs to have the following key properties:

Excellent displacement capability (i.e. elastic recovery performance), usually expressed in displacement levels (such as ± 20%, ± 25%, ± 50%, etc.), ensures that no cracking or peeling occurs when the joint repeatedly expands or misalignments;

Good weather resistance, able to maintain sealing performance and elasticity even after UV aging, high and low temperature cycling, acid rain erosion and other tests;

Compatibility with different substrates requires good adhesion with materials such as glass, aluminum alloy, stainless steel, and stone to avoid interface debonding;

There is no need to bear structural stress, so there is no mandatory requirement for strength. High modulus (high hardness, suitable for small displacement joints) or low modulus (good flexibility, suitable for large displacement joints) products can be selected according to the joint width and displacement.

Typical application areas:

Widely used in various types of curtain wall joints, such as horizontal and vertical joints in glass curtain walls, panel splicing joints in metal curtain walls, dry hanging joints in stone curtain walls, installation joints in clay panel curtain walls, etc. It is also suitable for sealing treatment at the junction of curtain walls and main structures.

相关产品