Summer glue usage precautions

Substrate surface is wet

China has a large area of monsoon climate. In summer, it is mainly affected by the southerly airflow from the ocean, forming a humid and rainy climate. Especially during the transition of seasons, various airflows interact with each other, resulting in hot and rainy weather with unpredictable changes.

After rain, if the substrate is accidentally wetted, do not start bonding immediately without checking the substrate interface in order to catch up with the work. If the interface is still wet, after the temperature rises under sunlight, the moisture in the glue seam cannot be discharged, which will cause bubbling of the uncured and relatively soft glue seam. Applying adhesive to a wet surface will also affect the adhesion between the tape and the substrate.

During construction, do not blindly pursue progress. The interface should be allowed to dry before injection.

Before construction, the bonding area should be confirmed to be dry. Construction should not be carried out on rainy days.

Substrate surface temperature is too high

In the hot summer, the sun shines on metal sheets, especially aluminum sheets, and the surface temperature can reach 80℃. When silicone weather-resistant sealant cures, the temperature of the bonding material cannot exceed 50℃. Applying glue at high temperatures can easily cause small bubbles to form on the surface of the substrate, affecting the overall bonding effect between the sealant and the substrate.

When the substrate surface temperature is high, the curing reaction rate of the adhesive will accelerate. If the contacted substrate (such as metal window frame and glass) has poor air permeability, at high temperatures, the gas released rapidly during curing can only escape from the partially cured glue layer, resulting in bubbles of varying sizes on the cured tape.

Avoid applying glue immediately after the substrate is directly exposed to sunlight.

Construction should be carried out according to the substrate surface temperature required by the construction process.

Adhesive is exposed to sunlight before curing

Exposure to sunlight immediately after injection will cause thermal expansion of the plate, resulting in compression on the glue seam and causing the glue seam to bulge outward.

After a period of curing after injection, a hard shell has formed on the surface of the adhesive. When exposed to sunlight again, it has a certain resistance, and the bubbling phenomenon can be reduced.

Avoid applying glue to the substrate surface under direct sunlight. Apply glue to the west or north side of the building in the morning and to the east or south side in the afternoon.

If it is necessary to apply glue to the surface under direct sunlight, appropriate shading measures should be taken.

Other notes

In the hot summer, in addition to preventing the most common bubbling phenomenon, some good construction habits are also important factors in ensuring the quality of outdoor glue application and accelerating the construction progress.

When the temperature is too high, the sag resistance of the sealant will decrease, the curing time will accelerate, and the use and repair time will be shortened, requiring special attention to the repair time. A surface drying time test should be conducted according to the site environmental conditions to determine the surface repair time after glue application, that is, surface repair must be carried out before the sealant surface dries.

During construction, do not blindly pursue progress. When there is frequent thunder and rain or the substrate and bonding surface are wetted by rain, outdoor construction should be stopped. Before applying glue after rain, it is necessary to check whether the inside of the joint is wet.

If it is necessary to construct at temperatures above 40℃ or below 5℃, or under other conditions that may cause bubbling, it is recommended to conduct small-scale bonding tests and peel adhesion tests before use to confirm good adhesion and no adverse phenomena before large-scale use.

During construction, the bubbling phenomenon of one-component weather-resistant sealant can be improved by changing the construction time, selecting products with fast deep curing speed, or taking appropriate shading measures to avoid direct sunlight.

The packaging box of the sealant product should clearly indicate that the product is fragile, pressure-resistant, rainproof, and sunproof. The product should be stored in a dry, ventilated, and cool place. Therefore, in summer, the sealant should be stored in a ventilated, cool, and relatively high place to prevent the sealant from being soaked by rainwater or even extreme weather, which may affect the shelf life and cause curing problems in the packaging; please use the sealant as soon as possible after opening.

Key words:

RELATED INFORMATION

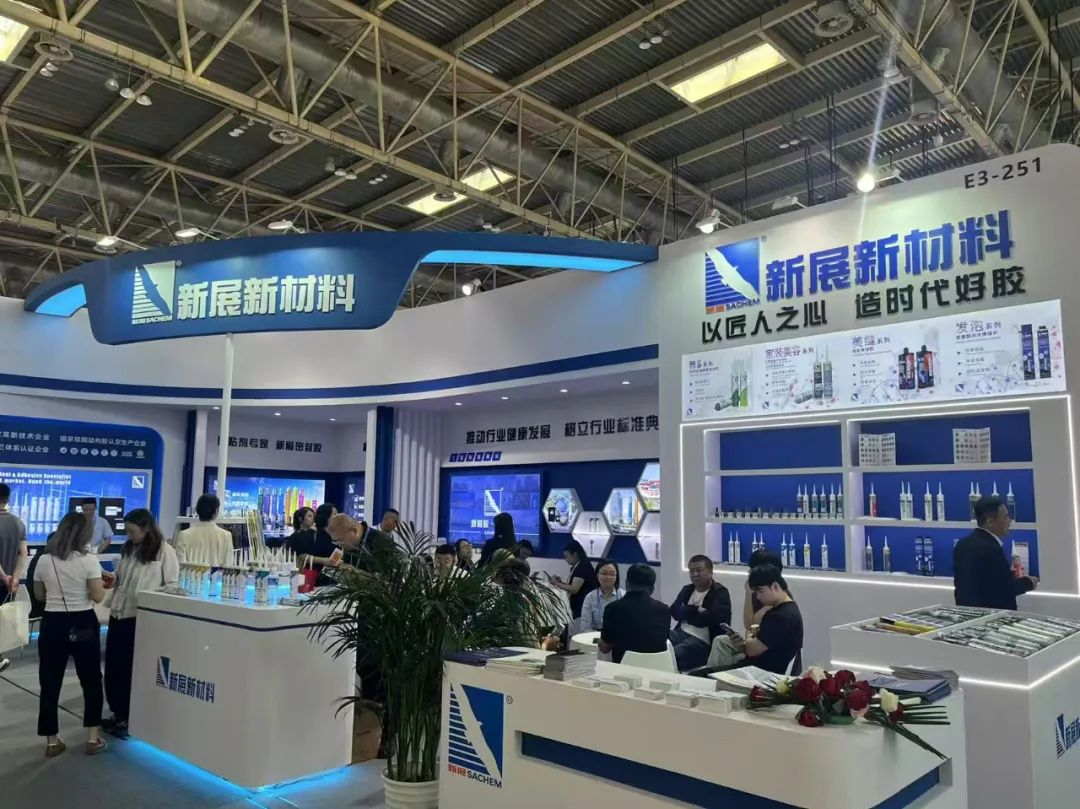

Dazzling New Exhibition · Shining in Beijing

May 29,2025

Aug 21,2023