High-quality doors and windows start with the "glue"

Window and door sealants are mainly used to seal gaps in doors, windows, and window frames, as well as gaps between window frames and walls. Their main functions are sealing, waterproofing, and airtightness. Although they are auxiliary materials for doors and windows, their cost accounts for a small proportion, but they play a crucial role in the overall performance of doors and windows. Improper selection and use will not only affect the overall decorative effect but also affect our basic needs for room comfort, warmth, and safety.

The quality of window and door sealants on the market varies greatly. It is crucial to choose high-quality sealants and avoid using inferior products.

Standards related to window and door sealants mainly include GB/T 14683-2017 "Silicone and modified silicone building sealants" and JC/T 485-2007 "Elastic sealants for building doors and windows". The selection of window and door sealants in China mainly refers to two standards: GB/T 14683 (such as Xinnian SJS7200/SJS2010) and JC/T 485 (such as Xinnian SJS10/SJS268).

It is generally believed that the deformation of window and door joints is small, and the displacement capacity requirement for sealants is not high. However, in reality, the displacement requirements of the joints vary depending on the structural design of the doors and windows. Currently, our company's window and door sealants have three displacement capacity levels: 12.5, 20, and 25, for users to choose from. Displacement capacity is a key indicator for measuring the elasticity of the sealant. The higher the displacement capacity, the better the elasticity of the sealant. Products with high displacement capacity have a stronger ability to withstand changes in joint displacement. For window and door joints with large displacement changes, it is recommended to prioritize products with high displacement capacity.

The unpredictable weather inevitably involves wind, rain, sun, and frost. Windows and doors must withstand both high-temperature baking and freezing cold. As a key material for sealing and waterproofing doors and windows, the weather resistance of window and door sealants must be good enough to ensure the service life of the doors and windows. Compared with other types of synthetic rubber sealants, silicone window and door sealants have the best weather resistance. However, the quality of silicone sealants for doors and windows on the market varies greatly. Cheap and inferior window and door sealants are prone to shrinkage, cracking, or powdering, leading to surface problems with the doors and windows.

These inferior window and door sealants usually contain a large amount of mineral oil. No obvious problems will appear when they are first used. However, the mineral oil filled in the sealant has poor compatibility with the cured silicone sealant. After a period of time, the mineral oil will gradually volatilize, and the quality and performance of the sealant will also decrease. If the adhesive containing oil comes into contact with insulating glass, the mineral oil will penetrate into the butyl sealant of the insulating glass, causing the butyl sealant to flow and resulting in a rainbow phenomenon in the glass cavity, affecting the sealing effect and appearance of the insulating glass.

High-quality silicone window and door sealants are also green and environmentally friendly building materials. Taking newly developed window and door sealants as an example, they are environmentally friendly products with zero formaldehyde and low VOC (volatile organic compound) content. During the gel curing process, keeping the indoor and outdoor ventilated, after the gel naturally cures, it will not pose a threat to human health.

At the same time, correct construction during the use process is also an important condition for ensuring the normal service life of doors and windows.

Before construction, ensure that the sealant is used within the shelf life specified by the manufacturer. At the same time, the adhesion and compatibility of the sealant with the substrate and related accessories should be tested. Only after the test results are qualified can it be used. Although the Xinnian series of window and door sealants have good adhesion and compatibility with most commonly used substrates and accessories, because the innovation of modern doors and windows is also reflected in the application of new materials, various new building substrates and accessories are emerging one after another. The surface characteristics of the substrate and the chemical properties of the accessories are not within the control of the sealant manufacturer. Therefore, adhesion and compatibility testing before use is very important.

Compatibility testing and adhesion testing can avoid extreme situations such as sealant corrosion of the substrate surface and non-adhesion. If there are dense small holes or visible physicochemical changes on the contact surface between the adhesive and the substrate, or if the adhesive is easily peeled off from the substrate surface, the type of sealant needs to be changed or the substrate surface needs to be specially treated.

The vast majority of window and door sealants on the market are one-component silicone sealants that need to react with water vapor in the air to cure. The curing process is also affected by environmental temperature and humidity conditions. The lower the environmental temperature and humidity, the slower the curing speed of the sealant. Too high a temperature will cause the sealant to cure too quickly, preventing it from fully wetting the substrate surface, thus affecting the bonding between the sealant and the substrate. Too high humidity will make the surface of the sealant difficult to clean after curing. The recommended construction environment conditions for Xinnian silicone sealant are: temperature 4℃~40℃, relative humidity 40%~80%.

Taking the upcoming winter as an example, the construction of window and door sealants in winter may reduce the curing speed due to low environmental temperature and humidity, thus affecting construction efficiency and quality.

In winter, the low temperature causes the substrate surface to easily produce frost or fog, resulting in moisture at the adhesive joint. If the substrate surface is not dry enough before applying the sealant, there may be water vapor, and the sealant joint may be wet, causing the sealant to bubble. Moreover, the moisture in the adhesive joint will affect the bonding performance of the sealant, thus affecting the construction quality. During low-temperature construction, it is necessary to fully confirm that the substrate surface is dry before construction.

In winter construction environments, the temperature and humidity are generally low, and the curing speed of the sealant may be significantly slowed down. During construction, it is recommended to extend the curing time of the sealant after construction to avoid causing large stress to the sealant joint after construction, so as to prevent joint deformation.

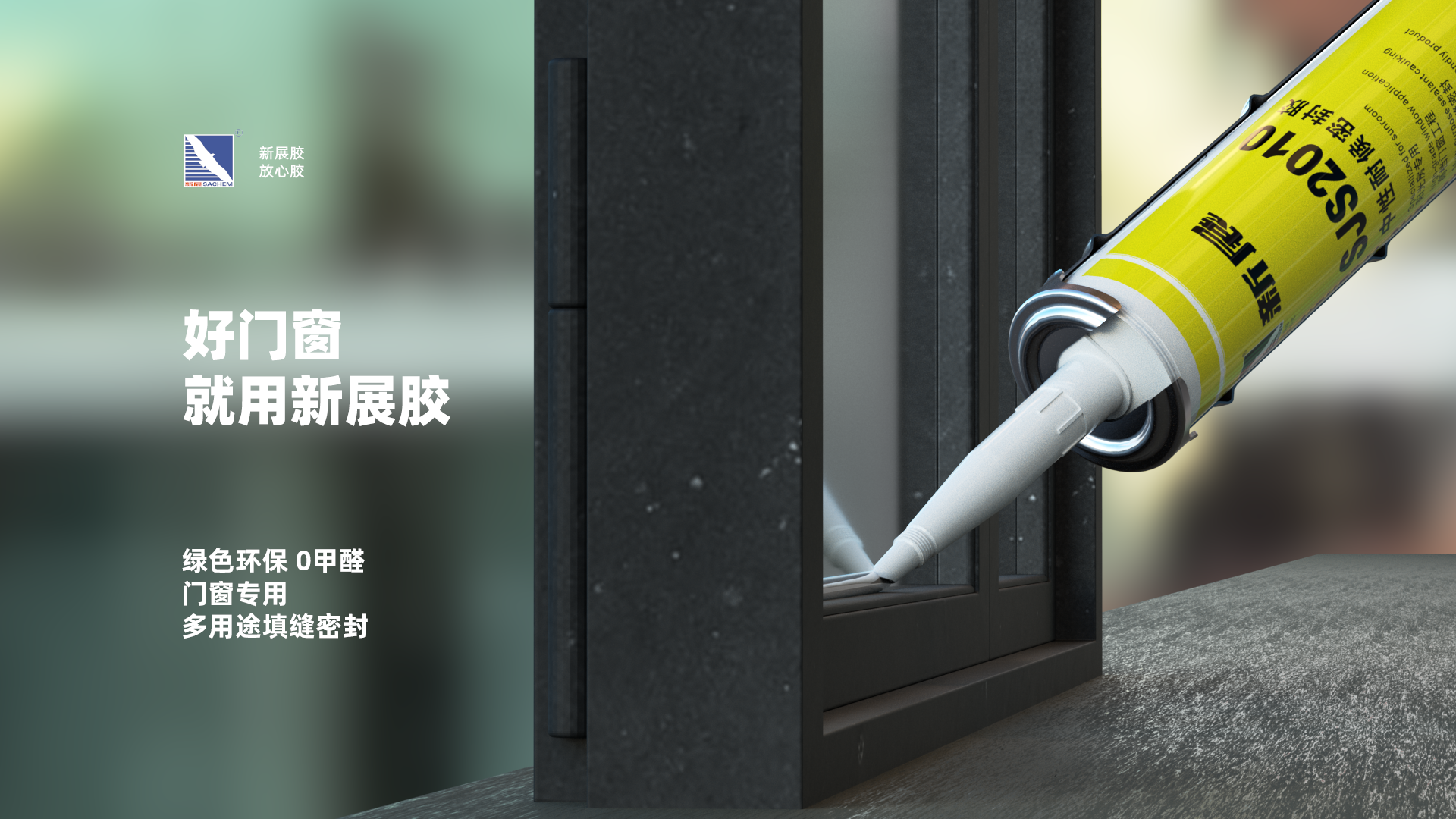

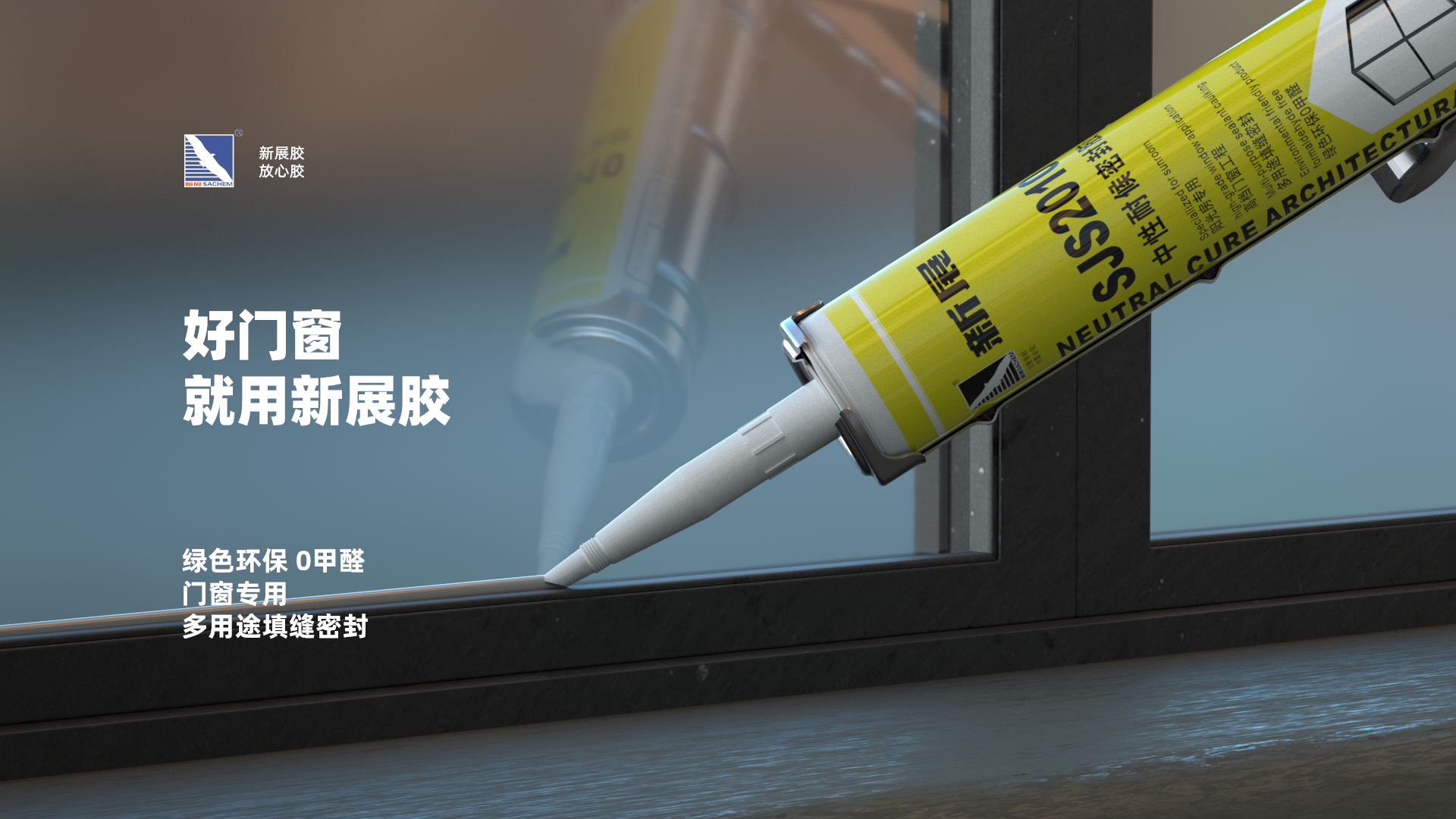

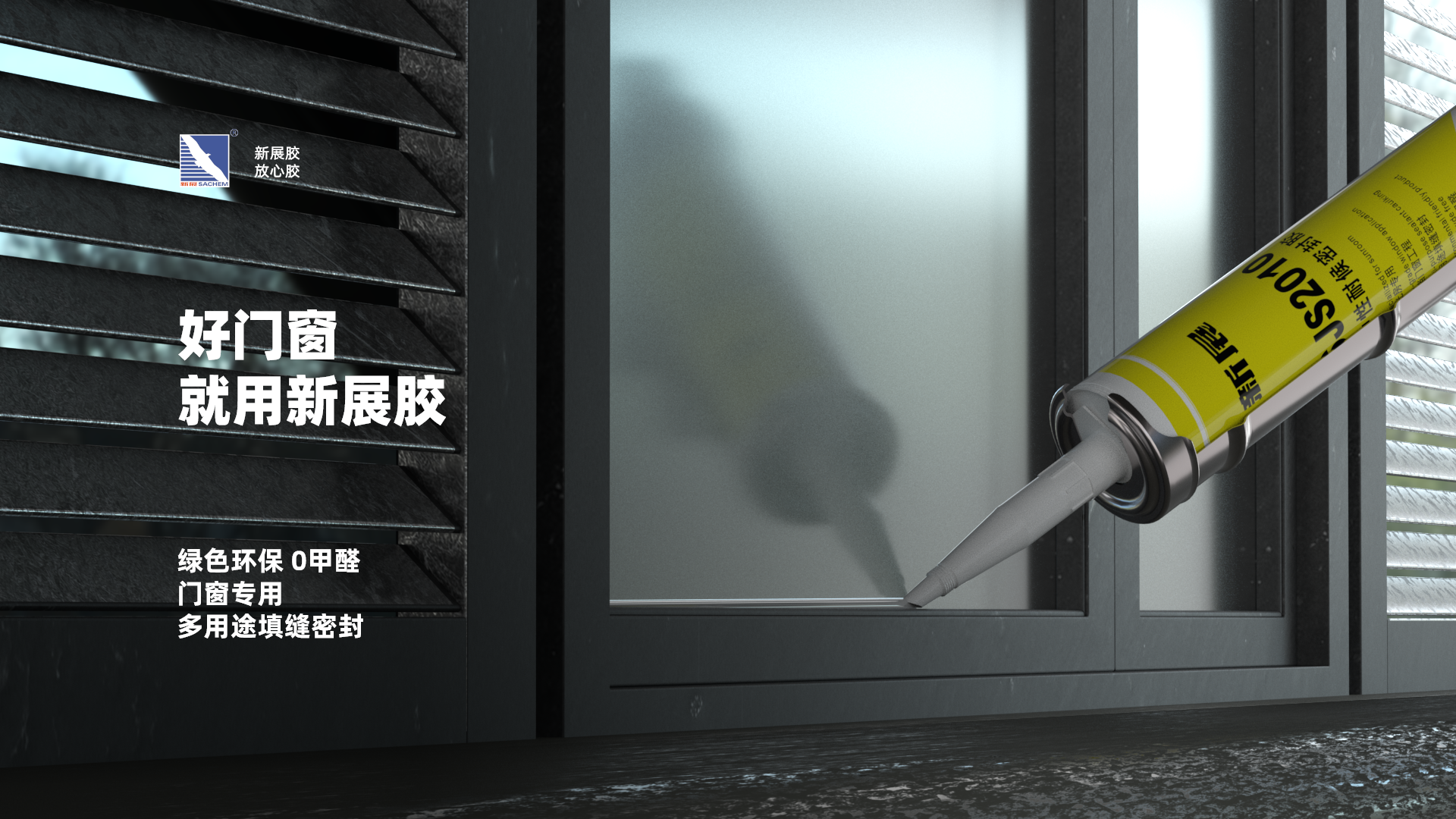

Recommended high-quality window and door sealants:

SJS2010 is a one-component, neutral, room-temperature vulcanizing silicone building sealant with excellent weather resistance and good adhesion to most building materials, requiring no primer. This product has a displacement capacity of 25, and can be used for sealing joints between various building doors and windows and walls, as well as for window sash sealing and other general building joint sealing.

Key words:

RELATED INFORMATION

Dazzling New Exhibition · Shining in Beijing

May 29,2025

Aug 21,2023