Selection and Use of Insulating Glass Sealant

Due to its heat insulation, thermal insulation, sound insulation, and anti-condensation properties, hollow glass is increasingly recognized as an energy-efficient and environmentally friendly product.

During use, hollow glass is constantly exposed to external water vapor penetration, wind and rain, ultraviolet radiation, temperature changes, and external forces such as atmospheric pressure and wind load. The combined effects of various environmental factors subject hollow glass to harsh conditions. Therefore, the sealant must be waterproof, airtight, radiation-resistant, temperature-resistant, and moisture-resistant. Selecting a high-quality sealant is one of the prerequisites for improving the service life of insulating glass.

Selection of Insulating Glass Sealant

Currently, the sealing and lamination processes in insulating glass production use a double-seal technology.

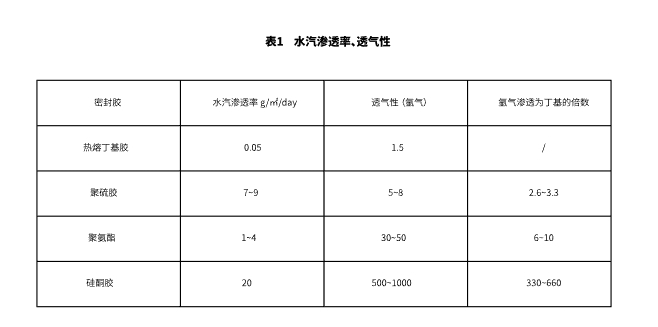

The first seal uses hot-melt butyl sealant (butyl sealant for short). Butyl rubber has an extremely low water vapor transmission rate, effectively preventing external water vapor from entering the insulating glass cavity and preventing inert gas from escaping the cavity, thus maintaining the long-term energy-saving effect of the insulating glass. Therefore, the first seal plays a decisive role in the airtightness of the insulating glass.

However, butyl rubber itself cannot be completely cured, and its cohesive strength and adhesive strength are relatively low. It has low elasticity and weak ability to prevent glass displacement. Therefore, butyl rubber cannot independently complete the assembly of insulating glass and requires a secondary seal to assemble a structurally stable insulating glass unit.

The second seal usually uses silicone sealant; in some cases, polysulfide sealant or polyurethane sealant is also used. The second sealant must have excellent strength, elasticity, and adhesion to glass. At the same time, the second sealant should also have good resistance to high and low temperature changes, as well as resistance to natural aging such as high humidity and ultraviolet radiation.

After sealing with two sealants, the insulating glass forms a structurally stable single component. The second sealant protects the first butyl sealant from displacement and delamination and assists the butyl sealant in providing airtightness.

Compared to the single butyl sealant, the water vapor transmission rate of the second sealant, such as silicone sealant, is relatively high. A comparison of the water vapor transmission rates of various sealants is shown in Table 1. Without the first butyl sealant, relying solely on the second seal would render the insulating glass airtight. Therefore, the double seal of insulating glass is indispensable; the absence of either seal would compromise the quality and function of the insulating glass.

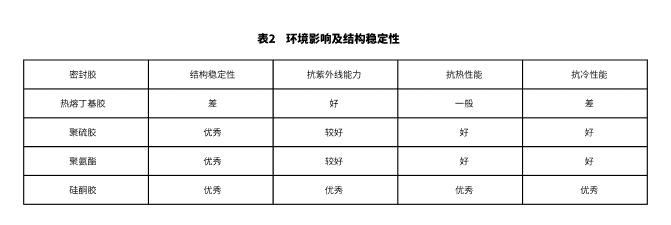

Since the airtightness of insulating glass is ensured by the butyl sealant, when selecting the second sealant, the airtightness of the second sealant is not the primary consideration. The second sealant is responsible for the structural stability of the insulating glass and its resistance to changes in the natural environment. The selection of the second sealant should be based on these aspects. A comparison of the stability and environmental resistance of various sealants is shown in Table 2.

From the comparison in Table 2, it can be seen that among several sealants, silicone sealant has the best overall performance in terms of structural stability, resistance to high and low temperature changes, and ultraviolet resistance. Therefore, silicone sealant is the best choice for secondary sealing of insulating glass.

Insulating glass used in hidden or semi-hidden frame curtain walls must use silicone structural sealant for secondary sealing. For insulating glass used in exposed frame curtain walls, silicone structural sealant is also recommended for secondary sealing.

Use of Insulating Glass Sealant

To ensure good sealing performance of insulating glass, in addition to selecting the correct sealant, correct use of the sealant is also an important aspect.

Using the correct cleaning agent and adhering to the specified surface treatment and cleaning procedures are prerequisites for achieving good bonding results. If the surface treatment is improper and the surface is not thoroughly cleaned before using the sealant, the sealant will not bond well with any substrate.

Applying butyl sealant is an important step in insulating glass production, and the quality of the butyl sealant coating determines the airtightness of the insulating glass product. The sealant must be applied evenly with a consistent cross-section. Carefully check for broken lines, bubbles, or impurities that may affect the appearance. If necessary, reapply or repair the sealant.

The second sealant is usually a two-component silicone sealant. The following points should be noted when applying the sealant:

1) The A and B components should be mixed according to the ratio provided by the manufacturer. Inaccurate proportions will cause abnormal curing speed of the sealant. If the curing speed needs to be adjusted by adjusting the amount of component B due to temperature changes or other reasons, the maximum increase or decrease in the amount of component B should not exceed ±20% of the normal amount. Too much or too little component B will affect the strength, elasticity, and adhesion of the cured sealant.

2) The A and B components should be thoroughly mixed and tested with a butterfly test. There should be no uneven color such as white filaments in the sealant.

3) The sealant should be applied evenly along one side to prevent bubble formation, and any residual sealant on the glass surface should be scraped off after application.

4) When applying the sealant, ensure close contact with the first sealant without leaving any gaps.

5) The width and thickness of the adhesive should meet the design requirements of the insulating glass unit.

6) Before using the second sealant, it is recommended to conduct a compatibility test between the second sealant and the first butyl sealant to ensure that no dissolution or reaction occurs before contact. Otherwise, it may cause the butyl sealant to flow or decompose, leading to sealant failure and affecting the appearance of the insulating glass cavity.

Causes of Insulating Glass Seal Failure

The direct manifestation of insulating glass seal failure is water vapor condensation (fogging) inside the insulating glass frame, which is caused by water vapor entering the insulating glass cavity.

The most direct cause of insulating glass seal failure is insufficient airtightness of the butyl sealant seal, leading to external air and moisture in the air penetrating into the insulating glass cavity. The main reasons for insufficient butyl sealant airtightness are: firstly, the quality of the butyl sealant itself, and secondly, uneven application of the butyl sealant. In addition, if the second sealant bonding is unstable, causing the butyl sealant to shift or delaminate, it may also affect the airtightness of the butyl sealant.

Insulated glass units (IGUs) are exposed to various environmental factors, such as fluctuating temperatures and atmospheric pressure, wind pressure, workloads, sunlight, water, and humidity, all of which can negatively impact the average lifespan of the glass. In particular, for the secondary sealant of IGUs, if it is directly exposed to harsh high-temperature and high-humidity environments, the lifespan and aging resistance of the secondary sealant will be significantly affected.

To improve the sealing lifespan of IGUs, high-quality butyl sealant and secondary sealant should be selected first, and secondly, the quality of the butyl sealant and secondary sealant application should be ensured.

When IGUs need to be used in harsh environments, during the design and installation of the IGUs, a sufficiently high external protective structure should be used for the edges of the IGUs to avoid direct contact between the sealant and the harsh environment as much as possible. This also helps to improve the sealing lifespan of the IGUs.

Key words:

RELATED INFORMATION

Dazzling New Exhibition · Shining in Beijing

May 29,2025

Aug 21,2023